Dynamic Machine Design

Industrial Expertise Providing Custom Engineered Solutions

Zero Liquid Discharge (ZLD): Phone: 1-587-599-5222

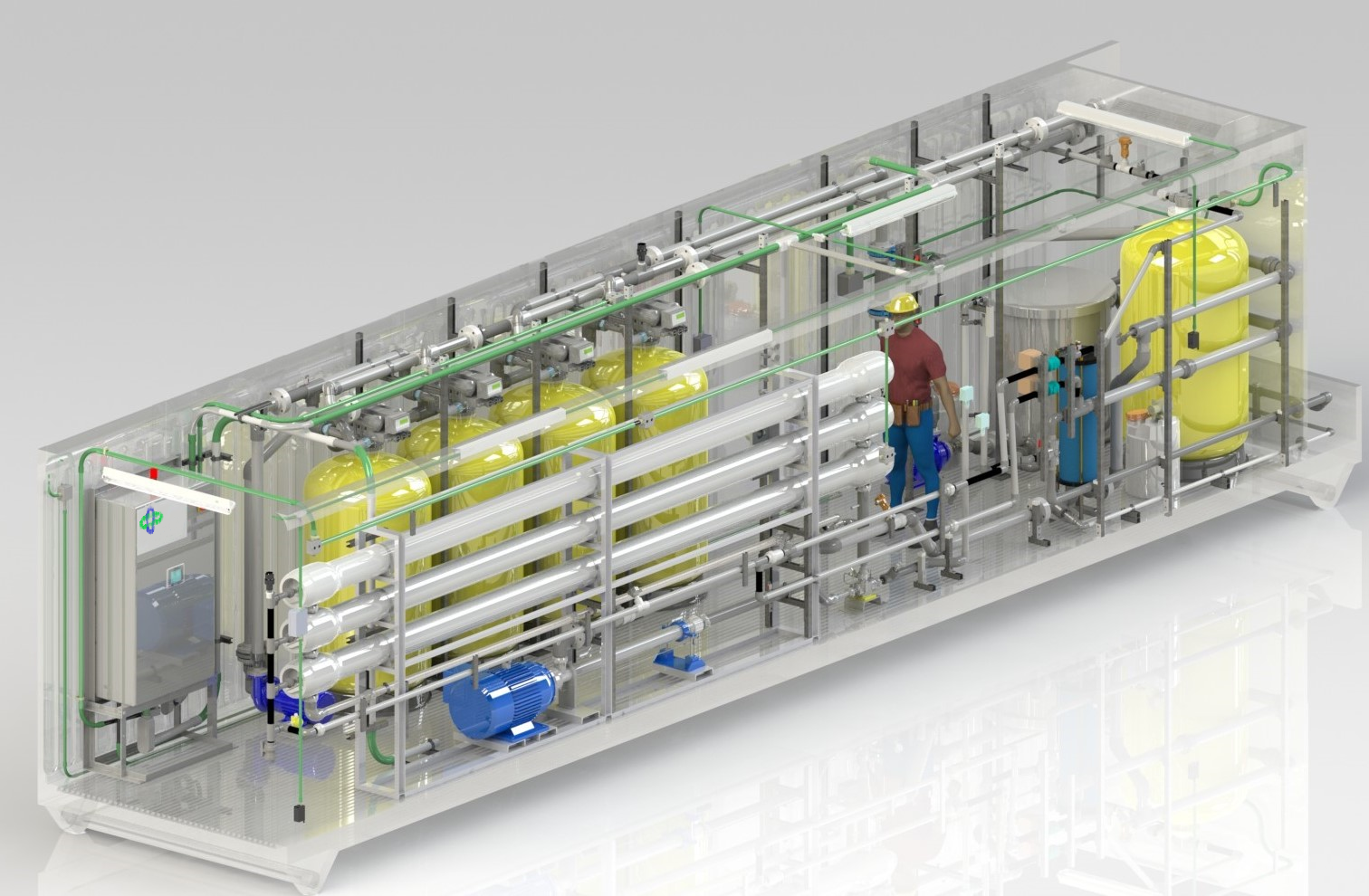

Pictured above is a two pass Reverse Osmosis Water Treatment plant that takes brackish water from seaside wells in Lima Peru and produces 732 gallons of 99.99% pure boiler feedwater every minute.

Water Reuse & Zero Liquid Discharge. (ZLD)

Zero Liquid Discharge requires the combination of numerous Wastewater Treatment Technologies, filters and purification methods, to be effective at taking your plant effluent and restoring it to influent quality. The system must also include sludge handling and dewatering. At Dyanmic Machine Design, we will custom Engineer a process and equipment into a complete system that will meet your Process, Health & Safety, and Environmental Compliance requirements, at the most economical and practical level.

At Dyanmic Machine Design, we work with Municipal, Agricultural and Industrial clients. If you have a work camp, resort, golf course, a food processing plant, a nuclear reactor, an oil refinery , a farm, winery or dairy, Dyanmic Machine Design can help with all of your water and wastewater treatment requirements, including recycling your wastewater for Zero Liquid Discharge.

The high quality effluent from an MF/UF/RO systems makes them ideal for incorporation into a Zero Liquid Discharge or water reuse application in industry or agriculture. Wastewater streams can be recycled into feedwater streams. Processing plants can recover water, reduce municipal infeed costs, meet Environmental Compliance, and not be paying to ship and dispose of water.

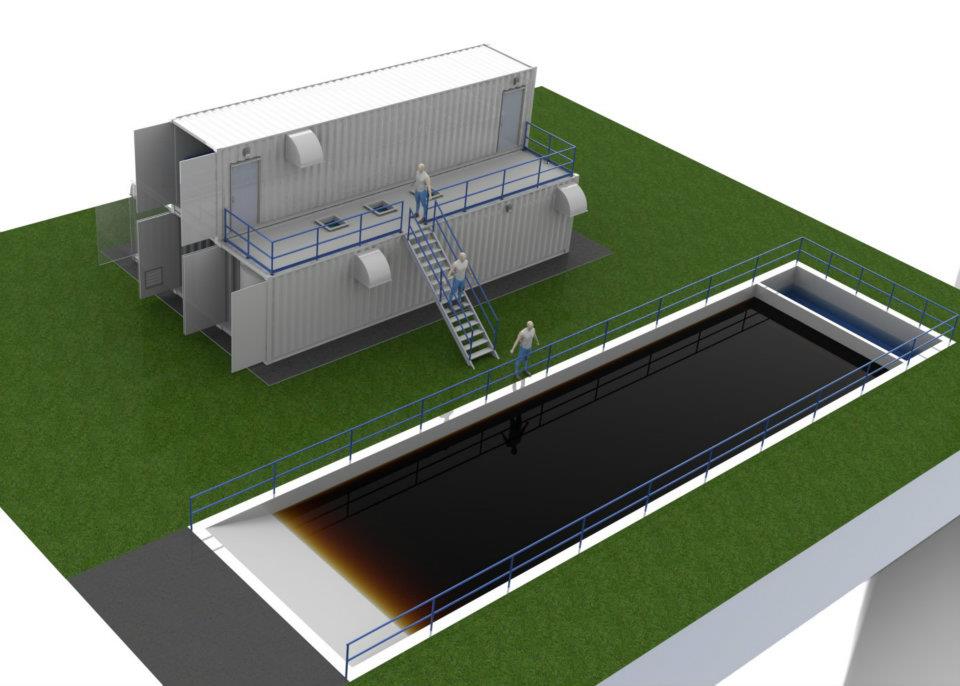

Dyanmic Machine Design provides full Engineering and process design along with manufacturing, equipment, systems and monitoring. We will design, build, test, install and commission your Zero Liquid Discharge project, all to your specifications to meet your needs. We also offer packaged plants, Pilot Plants and Containerized Systems.

Wastewater Treatement Technology Used in Zero Liquid Discharge

Reverse Osmosis (RO) Treatment

If you are looking to produce a truly crisp, clean, pure water, Reverse Osmosis will get you there. RO systems will find their way into drinking water production, desalanation, and boiler feedwater systems. Reverse Osmosis Water Purification Systems have the added advantage of being a positive stop to contaminants; not only are you getting clean water, you are taking the extra step to prevent any cross contamination.

The system on the right is a Containerized Reverse Osmosis Water Treatment system that was designed to provide drinking water for mining operations in the mountains of South America

High Quality Effluent. The membrane acts as a positive stop for all solids including salts. They can even filter out large molecules like Uranium. This is very important when you face strict effluent restrictions for Environmental Compliance. Reverse Osmosis Water Treatment Systems have one of the highest, most predictable effluent qualities of any Wastewater Treatment Technology. But, to get performance and life out of an RO System, we have to pretreat the influent water to coarse clean it.

Reverse Osmosis will not remove all contaiminants, (gases for example will pass through), but are quite efficient with contaminants such as trihalomethanes (THM's), some pesticides, solvents and other Volatile Organic Compounds (VOC's) as well as salts.

Ultra Filtration (UF)

Ultrafiltration Wastewater Treatment Membranes will remove particulates from water with up to a 4-Log reduction of Coliform Bacteria, producing potable water. There are various UF Membrane types, configurations and materials. Each will work best in certain environments. Dyanmic Machine Design will provide the best membrane for your specific requirements, and ensure that you are within regulatory compliance and environmentally sustainable.

Micro Filtration (MF)

Microfilration Wastewater Treatment Membranes are a standard in the water/wastewater industry. We incorporate it into every Reverse Osmosis system as a coarse pre-treatment to extend the life and effectiveness of the RO Membranes. MF is also a cornerstone of process wastewater treatment. It economically and handily removes the Total Suspended Solids (TSS) from a wastewater stream, and pretreats influent for both UF and RO systems. A good MF prefiltration system can allow an Ultra Filtration system to turn muddy water into potable drinking water, and an RO to take brackish well water or ocean water and create boiler feed quality.