Dynamic Machine Design

Industrial Expertise Providing Custom Engineered Solutions

Membrane Bio-Reactors (MBR): Phone: 1-587-599-5222

Wastewater Membrane Bioreactors (MBR's)

Membrane Bioreactors for treating Organic, Biological Wastewater steams found in municipal, industrial, pharmaceutical and agricultural wastewater treatment offer many benefits over older, conventional technologies.

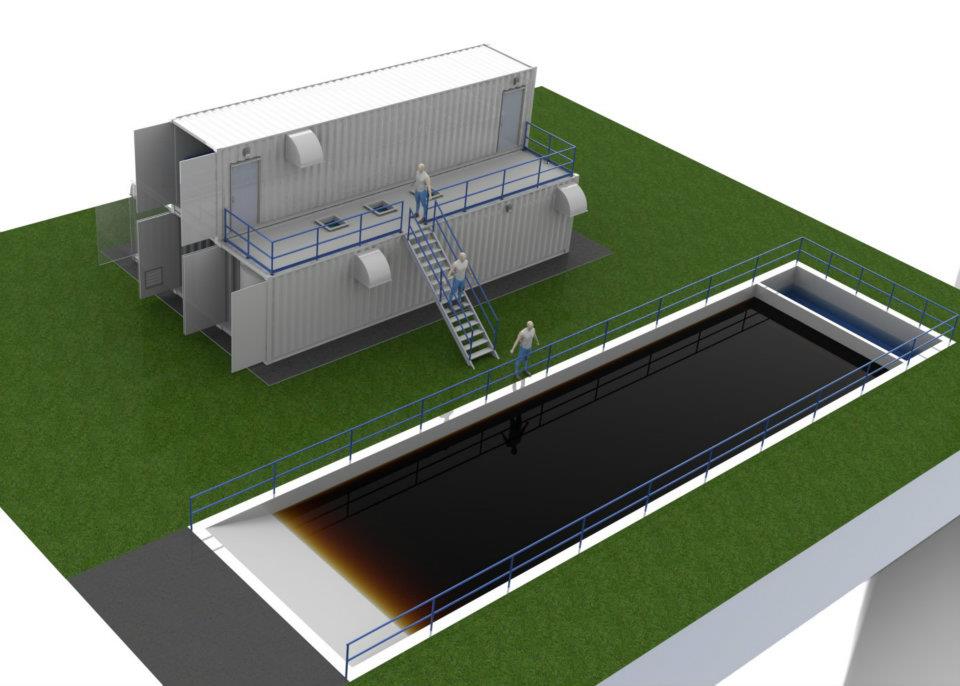

Small Footprint. Because they run with higher concentrations of solids than other technology, with MLSS (Mixed Liquor Suspended Solids) of up to 15,000 ppm, their tanks do not need to be as large. This is a great advantage for work camps and remote areas. It also play a huge benefit when attempting to upgrade an existing system, where real estate is at a premium, or in an existing plant where there simply is not a lot of room.

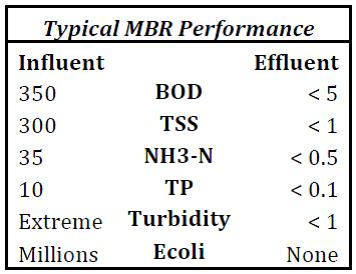

High Quality Effluent. This also translates into Environmental Compliance. The Filter Membrane acts as a positive stop for all solids greater in size than the sub-micron pore size of the membrane. This is very important when you face strict effluent restrictions. MBR's have one of the highest, most predictable effluent qualities of any wastewater treatment technology. Below is a table of typical Membrane BioReactor effluent results.

Variable Flow Rate. The Membranes in the MBR's do have a maximum draw rate but can ramp down to lower flows. This is very helpful for places like resorts where usage varies by time of the week and by season. The variable flow ability also enables the system to be run below peak rates, extending the useful life of the membranes, and be ramped up to peak to allow the cleaning and maintenance of individual Membrane Modules.

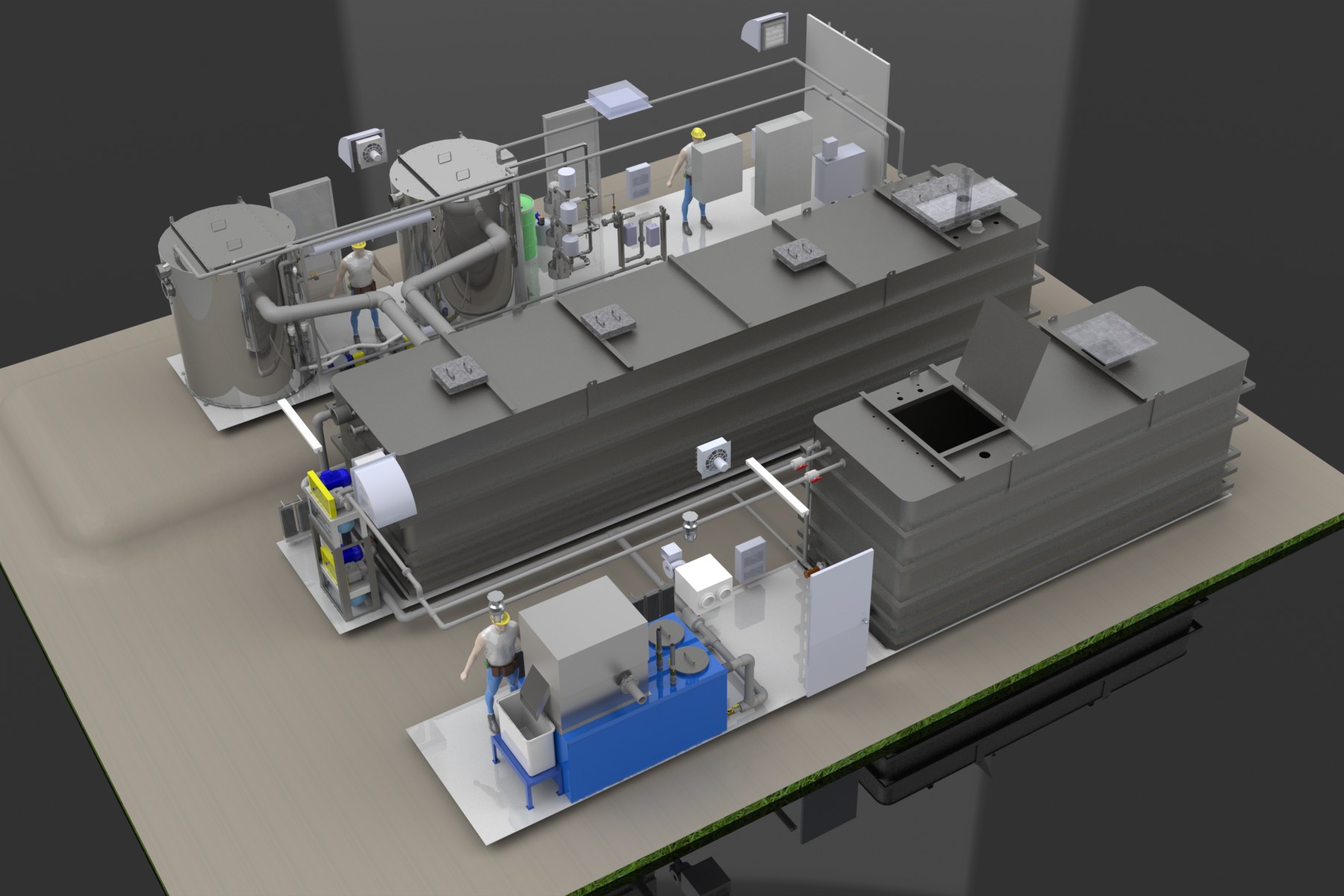

Wastewater Treatment Modular Design.

Dynamic Machine Design will engineer and build you a Membrane Bioreactor Wastewater Treatment System to suit your current needs, and when those needs increase in the future, we can simply upgrade with more MBR Filter Membrane Modules. MBR technology is also the ideal method for increasing the capacity of an existing cast in place Wastewater Treatment Plant, even one using different technology such as an SBR (Sequencing Batch Reactors) as commonly found in many cast-in-place wastewater treatment facilities. The significantly lower footprint of the MBR, its modular design, higher operational MLSS and superior effluent combine to provide the optimum, seemless upgrade.

Water Reuse and Zero Discharge. The high quality effluent from a Membrane Bioreactor makes it ideal for incorporation into a Zero Liquid Discharge or Water Reuse application. For example Dynamic Machine Design build a system for a restort that will take the effluent from the MBR, polish it up, and use it for flushing toilets, washing machines and irrigation of the golf course and gardens.

Dynamic Machine Design works with agricultural, municipal and industrial clients. So if you have a work camp, resort, golf course, a food processing plant, a nuclear reactor, an oil refinery , a farm, winery or dairy, we can help with all of your water and wastewater requirements.

Dynamic Machine Design provides full Engineering and process design along with manufacturing of equipment and systems. We will design, build, test, install and commission your project, all to your specifications, to meet your needs. We will then help you to monitor and maintain your system. We also offer packaged plants and Containerized Systems.