Dynamic Machine Design

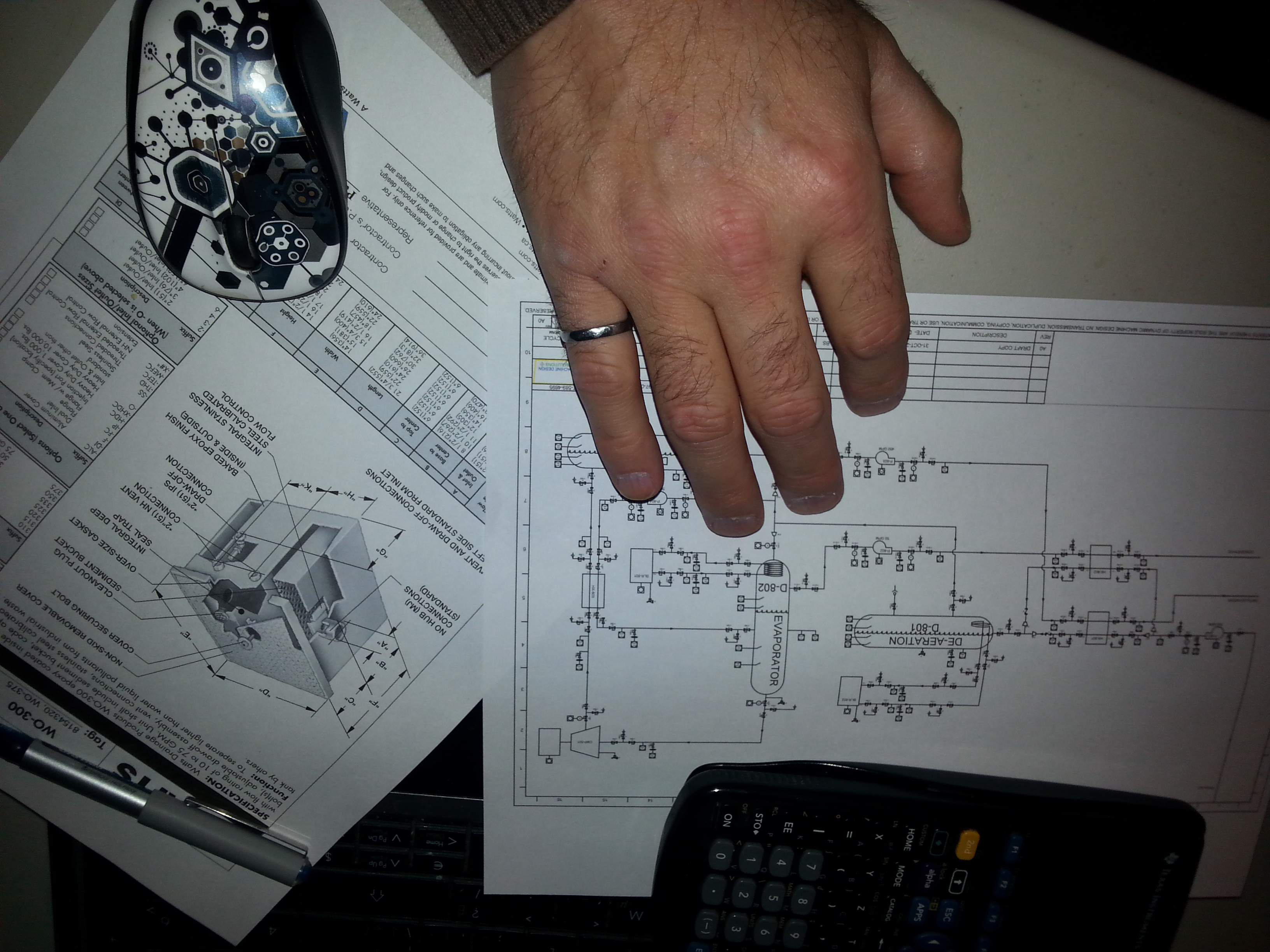

Industrial Expertise Providing Custom Engineered Solutions

Edmonton Office Phone: 1-587-599-5222

Custom Tooling Design

- Process Mechanical Designing custom processes and equipment.

- Process Flow and Flow Controls Instrumentation and controls for custom tooling.

- Tool Design Mechanical Design, engineering, drafting of customized tooling solutions.

- Integration Building systems to integrate custom tools into your existing processes.

- Hazardous Locations (Heat, Cold, Pinch Points, Moving Parts, Under Ground, Explosive or Poison Gases)

In every industry there are requirements for specialized tooling that does not exist off-the-shelf. For example, we have designed a system to allow entry into crude tanks through valves as small as 3" to take samples of the sludge at different levels in the tank. Similarly, for the same company, we designed a system to inject high pressure water to break up sand deposits with an extraction system, and full water recycle, that fits through a 4" valve on a tank.

Jigs and Fixtures

- Material Handling Equipment and Systems Fixtures and tooling as custom addons to existing equipment and machinery.

- Assembly and Manufacturing Jigs and Fixtures can speed up simple construction and assembly, reduce waste and increase safety and quanity. A simple example is a small jig we designed for a Class II Medical Device manufacturer that allowed tapping of three holes of different sizes simulataneously in a part. Tapping those holes used to take 2 minutes per hole including set up time, and they made upwards of 30 per day. We could do all three in less than 30 seconds including set up time. Time saved by Client was about 1000 hours per year.

- Packaging Systems Jigs and Fixtures to aid simple manual tasks that do not warrant full automation. This can be as simple as a form for folding T-Shirts, or an envelop sealer.

- Parts Feeding Nothing slows down assembly and construction more than having to fish through boxes for parts. We can design and build an simple feed system for any parts, allowing your staff to concentrate on the more critical tasks.

Are you looking for ways to expand capabilities, increase productivity, and enhance profitability? The answer may be simpler and more affordable than you think. Dynamic Machine Design's custom designed and engineered Automation have optimized the quality and efficiency of product assembly, boxing, filling, packaging, palletizing, testing, and inspection processes for a wide range of customers in every industry.

Custom Automation of Equipment and Processes solves numerous problems. It decreases waste, cycle time, rework, and labor minutes per unit. Automation does not take breaks.

- You get a Higher Return on Better Parts!

Dynamic Machine Design is a custom machinery and equipment Automation, Engineering and Design company providing a full range of engineering, process, mechanical and fabrication services, specializing in Industrial Automation. Whether you are ramping up for a new product or model, retrofitting an existing line or upgrading to comply with new safety regulations, Dynamic Machine Design is here to help.

Our dedicated in-house Engineering team will work one-on-one with you to develop the best overall Automation solution to meet your specific needs. Everything we develop adheres to our design philosophy of simplicity, ease of operation and maintenance, with the lowest overall cost of ownership over the lifetime of the equipment.

Our Project Teams are multidisciplinary, drawing on deep skills, training and experience in Mechanical, Process, Electrical and Automation Engineering along with the application of integrated test, machine vision and process intelligence. Every system is reviewed by our Staff for Process Validation, Material Specifications, Manufacturability, Efficiency, Operation and Maintenance. By doing our process analysis, Engineering and design homework up front, we consistently deliver the most robust, reliable Automation Solutions, that give our Clients a competitive edge.

Call or Email Dynamic Machine Design today for a free Custom Automation Consultation!